MAGNOM FLUID CONDITIONING TECHNOLOGY

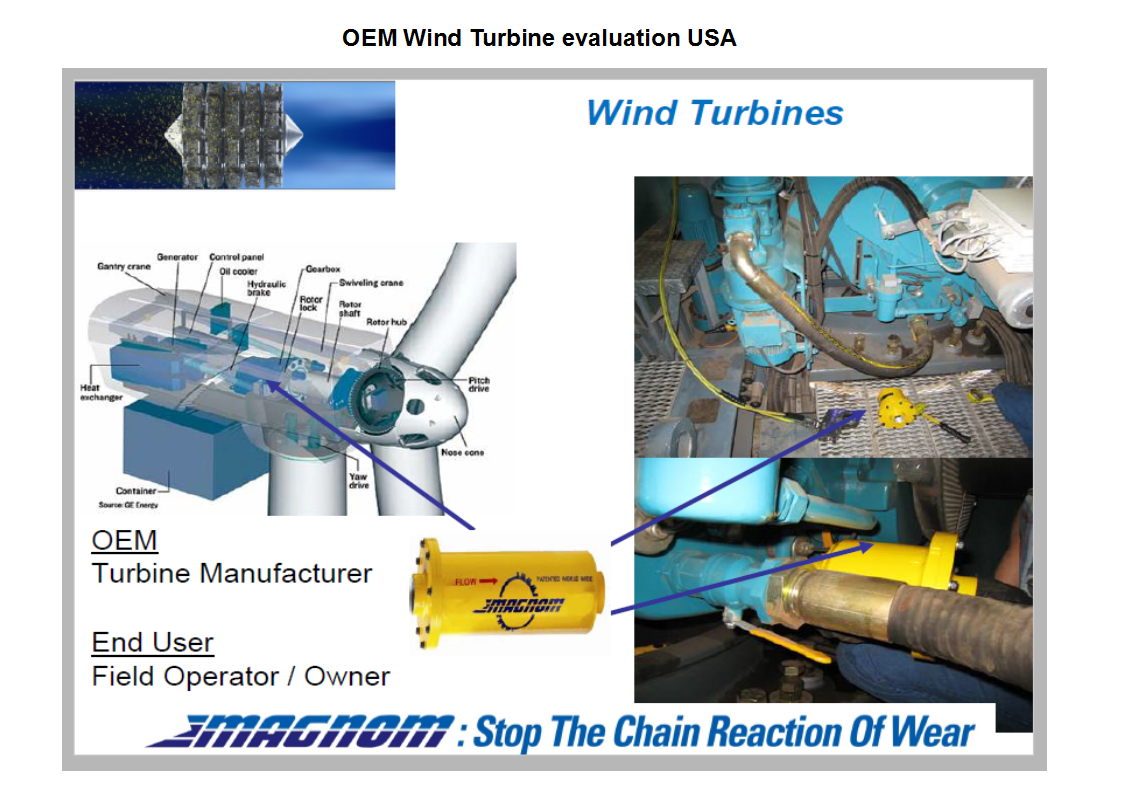

Installed in gearbox installations on numerous severe duty applications have practically eliminated gearbox failures!

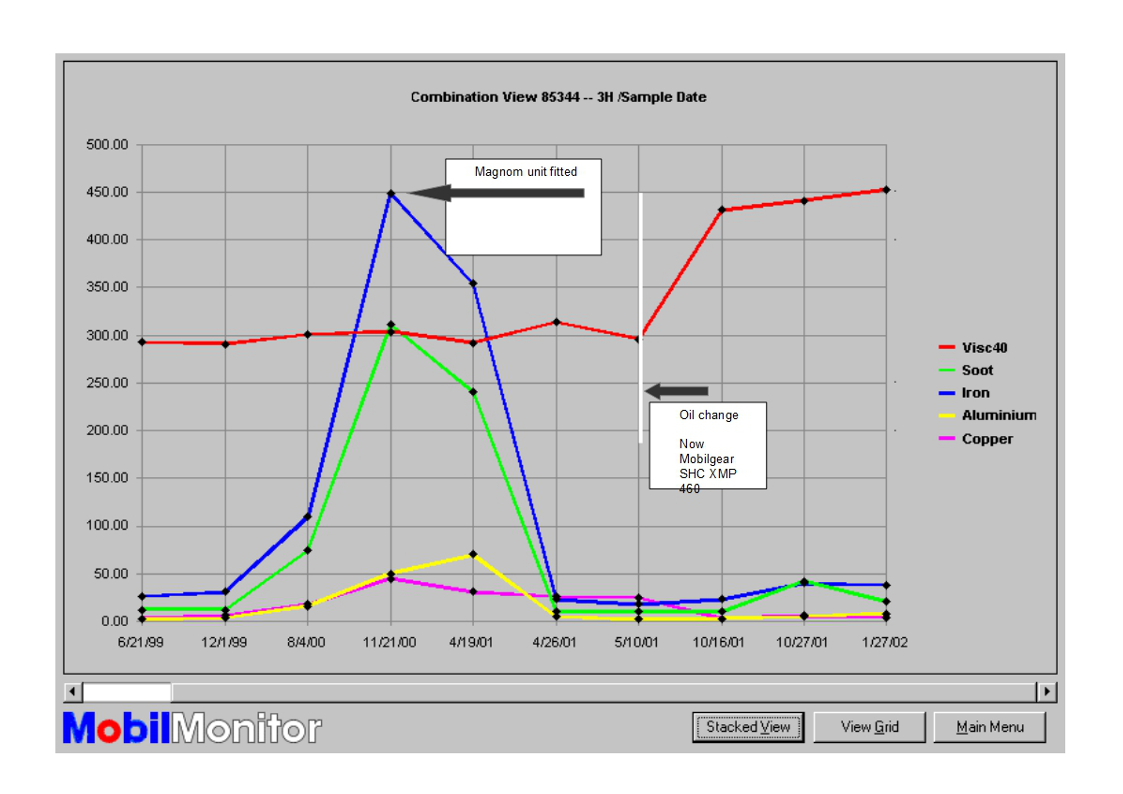

Gearboxes used in a number of 24/7 severe operating conditions at a number of power generating facilities in Europe were experiencing an annual gearbox failure rate of 42.8%.

After installing MAGNOM Inline Process units on the gearbox lubrication systems, the failure rate dropped to 0.0%!

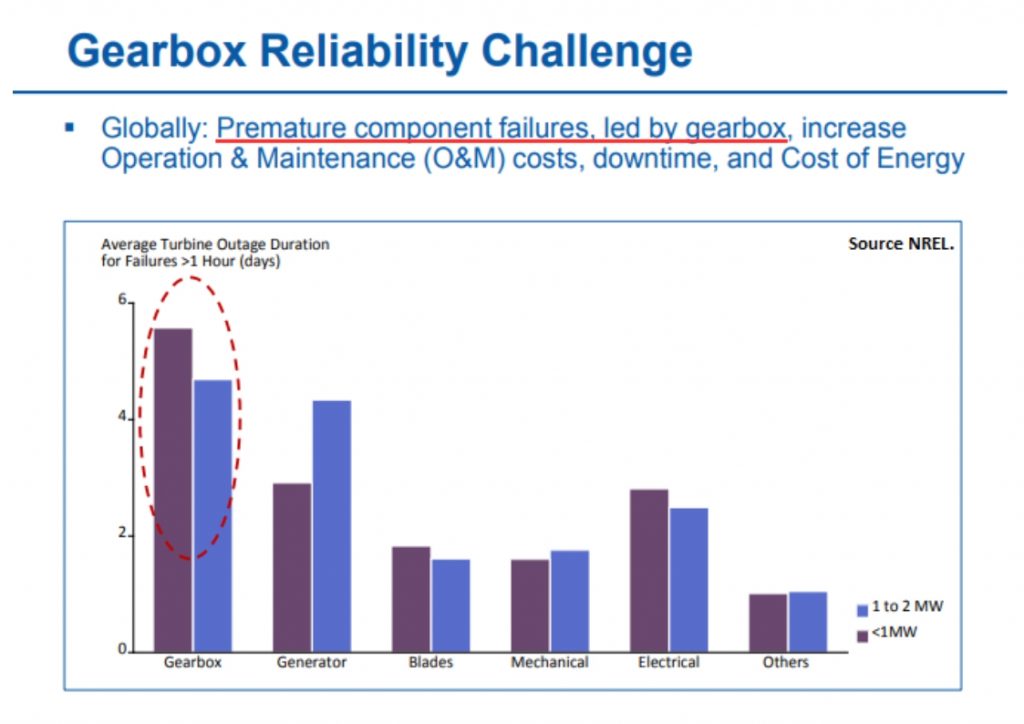

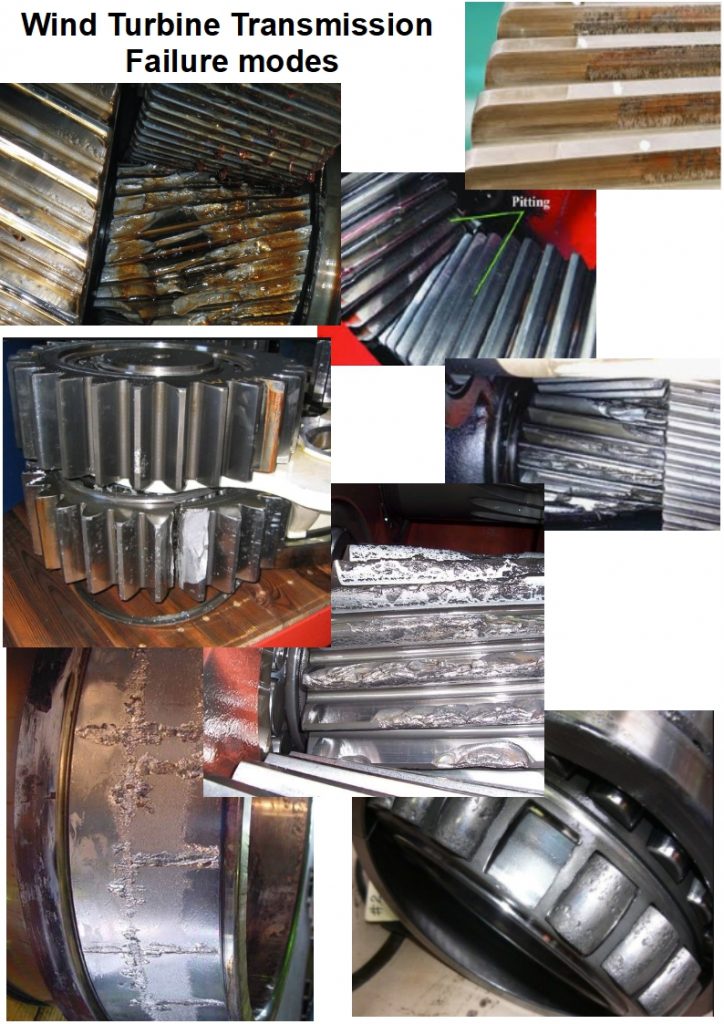

It has been determined by the NREL that most gearbox problems are generic in nature and not specific to a single turbine or gear manufacturer.

The NREL has also determined that the majority of gearbox failures appear to initiate in the bearings. This despite the fact that most gearboxes incorporate the best bearing design practices available.

Clearly, the problem meeting the established 20 year life expectancy for wind turbine gearboxes is not related to material or design flaws in the gearbox. The problem is that lubrication contamination leads to accelerated wear, which in turn causes higher maintenance costs, lost energy production and significantly increased initial equipment prices to cover the inevitable warranty issues.