Efficient Magnetic filters now offer a huge advantage in increasing the performance of existing Filtration units and Filter systems / fluid conditioning, and play the major part in improving reliability, reducing system running cost and increasing availability, by effectively and efficiently removing Ferrous contamination, Iron oxide, from critical fluid systems, down to sub micron levels, This is especially important for maintaining the accuracy and repeatability of test equipment

Hydraulics repair

Amongst many worldwide system and component repair shops and OEM’s This large Midwestern US hydraulic repair company uses Magnom filters on their Schroeder Brothers testing machine.

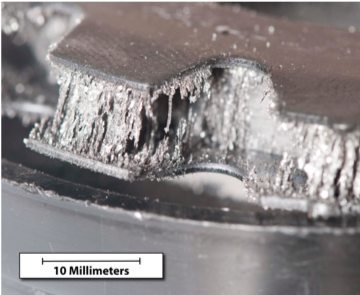

They had realised that the standard 25 micron canister filter was not able to remove ferrous contamination that is introduced when they first start up and test the units after refurbishment. Now, a Magnom Midi, easily installed In-Line, eliminates contaminants and debris before refurbished units are returned to the customer. Post-rebuild start up wear is greatly reduced and refurbished pumps experience a longer life.

Whayne Cat, Kentucky,

Whayne CAT of Kentucky, employed Magnom products on their service & test truck,

To ensure that customers equipment was returned to the vehicle following refurbishment, in 100% clean condition, free from wear and failure debris once repaired.

Such was the success experienced by using Magnom products, Whayne CAT now supply Magnom products as a strategic partner into the off highway industry and CAT equipment distributors across the USA :-