Prevent Hydraulic and lubrication system failures!

To truly understand the true benefit offered by Magnom Technology :-

I often ask fellow engineers to just forget the inherent limitations of conventional sieve filtration for a moment, as I would not want any previous experiences to limit the thought process in understanding the unique performance & benefits offered by the Magnom proposition.

Essentially conventional filers are sieves, and are size discriminate/filter by particle size!

But in our systems…the particulate/contaminant size is not the actual threat,

eg a 10 micron particle of say fibre offers little threat when compared to say… a 10 micron particle of high carbon steel.

But a conventional filter treats these materials as the same, because it only addresses size and not the threat posed to our systems!

Our history in the treatment of fluids here at Magnom teaches us something very import and very obvious in hind sight.

85 +% off all industrial and commercial products produced globally are manufactured from steel and iron.

- So it is perhaps no surprise that the majority of damaging contaminant trapped in products/fluid systems during manufacture are steel and iron!

- Also during the break in (running in) process the contact surfaces that are breaking in against each other are predominantly high carbon steel!

- Again… normal wear and tear experienced during system use, high carbon steel particles are again produced and are circulating in the fluids.

This aggressive contamination is responsible for the start of the “Chain Reaction of Wear” and subsequent catastrophic failure!

To quote;- Jim Fitch of Noria :-

“The worse things get,

the faster things get-worse”

So!

We do not have to be particularly well informed to understand that these super-hard & super-sharp high carbon steel contaminants are the greatest threat to the health and availability of any fluid system (its essentially bits of the system killing the system itself),

These high carbon steel contaminants are also very small (typically sub 10 micron)

this is because they are torn from hard contact surfaces, these surfaces don’t shed material easily. so they are torn from these contact surfaces as very small particles,

Having been torn off they are also angular and very sharp.

So it makes sense to treat these contaminants as the primary threat to our systems,

be they industrial lube, or say hydraulic systems or indeed Formula 1 race systems.

What ever the system Magnom offers a truly unique strategic answer to this 80 +

year old problem.

A problem that has been largely ignored while the only solution available was a sieve or a magnetic drain plug!

In-fact think about it… why would OEM’s & system designers fit magnetic drain plugs… if conventional filters do the job we need them to?

Magnetic plugs simply would not exist, if conventional filtration were capable of removing this damaging material effectively.

The Proposition…

Simply!

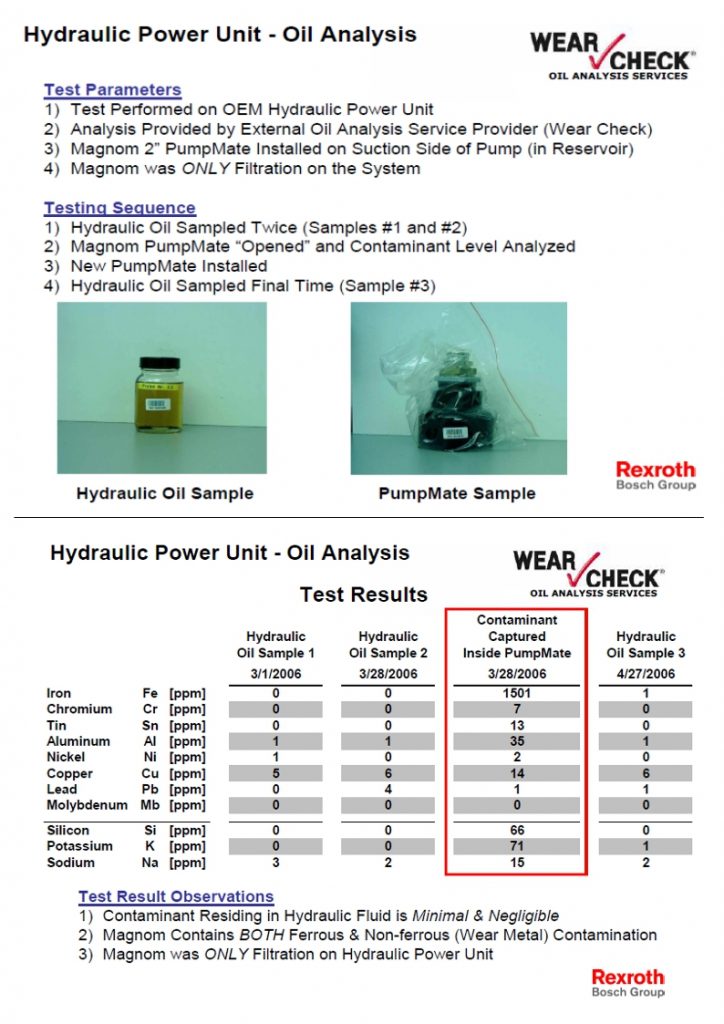

Ideally remove the greatest threat to the system, ‘absolutely’ before the systems pump!!!

i.e. Before it is delivered to the valves and the rest of the system by the pump, causing expensive unnecessary and expensive damage…. on the return to the reservoir ‘after the damage is done’ on its journey through the critical components in the system!

In achieving this MagnomTM brings a host of performance and health benefits to these

fluid systems as a whole!

Longer equipment life, reduced maintenance/repair, higher system/product availability, to work for us.

Also with the Magnom product range you can strategically protect critical components and operations at any location in the system ‘high or low pressure’ without fear of cavitation or flow restriction and bidirectionally (flow can be in either direction).