NEW MAGNOM Partner,…. ‘KLEEN OIL Co’ of COLOMBIA,

www.filtrosmagnom.comhttp:

Have initiated a series of validation testing and analysis, on customer HEAVY DUTY rough service mining equipment, to demonstrate the effectiveness and value of using MAGNOM technology.

Along with the added value the technology can deliver to customers and end users, here are details outlining the fantastic results seen during evaluation and customer benefits experienced.

Magnom Corp are very excited about the new partnership with ‘Kleen Oil’ Colombia, and to also see their test results reflecting the same benefits, seen world wide across many industry applications, from using this innovative technology.

First Results

Two months after having installed the MAGNOM Technology in ARGOS equipment,

When the service interval was reached and the ‘oil filter’ on their BUCRUS RH40E SHOVEL.

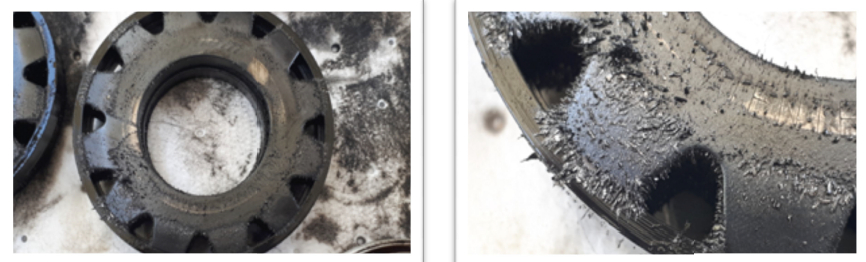

It was immediately possible to visually see the accumulation of aggressive metallic particulate removed from the oil, evident in the core of the Magnom filter unit, as can be observed in the images below.

When checking the Magnom Unit (magnetic filter) large amounts of damaging ferrous particles could be easily seen, imagine this debris recirculating around the system ‘time and time again’ unable to be removed by the conventional filters?

ARGOS consulted their CAT dealer, about the condition of the engine that had been repaired 3 months earlier.

Not only had the Magnom technology removed all of the ‘Break-In’ debris from the fresh engine, but also protected the engine from a mistake during re-build, causing even more ferrous generation.

Fortunately the dealer was able to correct the fault, and the engine was able to continue operation, without further damaged,

In this case, the MAGNOM magnetic filter not only protected a very valuable engine from the highly aggressive iron particles in the oil, by reducing friction & attrition in the engine, but importantly served as a prevention of failure, ‘and an early warning indicator’ for the customers engineers.

Saving a very valuable engine & machine from damage & failure, and also saving revenue, but also enabling the machine to remain available and to continue to work, generating revenue for the customer/user.