Extending the performance and life of Wind Turbine, Production, Locomotive, Vehicle & transmission, Gearbox and Drive systems

Magnom is/was utilised to filter high viscosity lubricant.

ExxonMobil chose Magnom Separators because of their belief that Magnom did not filter or remove additives from the fluid.

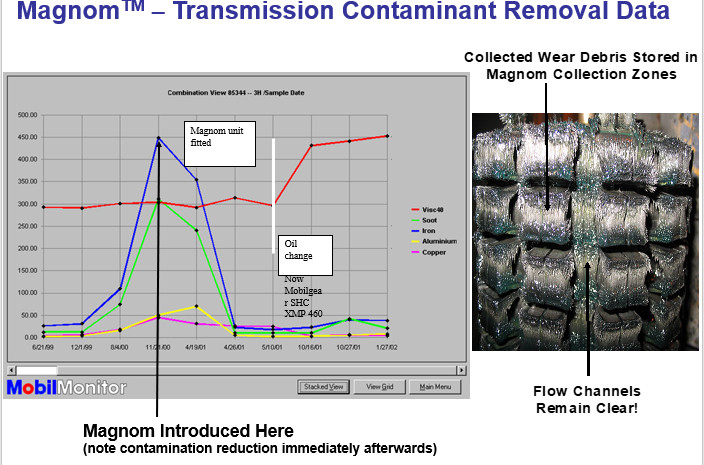

Preceding Mobi Monitor Oil Analysis graph depicts Magnom reducing Iron content from 450ppm to 25ppm.

Interesting result was that removal of iron particles reduced the chain reaction of wear. Meaning, the rapid generation of wear metals from abrasive contact with ferrous particles decreased significantly.

ExxonMobil claimed that 60% of the captured particulate was non-ferrous. Reason being that the soft wear metals and soot agglomerated/congealed to the hard, sharp ferrous metals. When the ferrous was removed, a portion of the non-ferrous was also removed. We can not be sure of the specific reason for this phenomenon categorically. but the client enjoys the benefits of this result.

Notice Aluminium decreased from 75ppm to 10ppm. The Aluminium was generated as a result of component wear.

The timeline samples were discrete events.

Notice the sample dates April 19, 2001 through April 26, 2001 are close together and highlight a significant change in contamination levels over a short time period for a a very viscous fluid using by using Magnom Products.

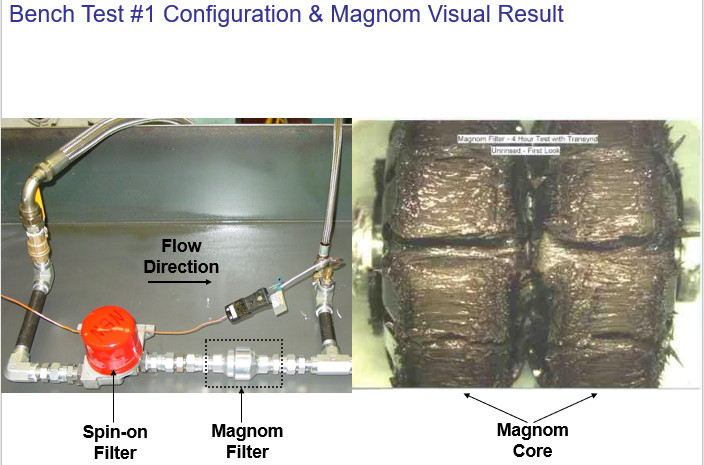

For the purpose of the 1000/2000 transmission bench test, 400 mg of pure iron particles (10 microns and under) were combined with approximately 40 L of transmission oil. The oil was then cycled through the system in the direction shown for approximately 4 hours, passing first through the brand new spin-on filter and then past through the Magnom.

Surprisingly, the Magnom contained approximately 6000 mg of contaminant at the end of the test cycle. It was determined that initial cleaning of the transmission oil prior to the test was insufficient. The cleaning process used a new spin-on filter from the 1000/2000 series transmission to cycle the oil for 36 hours. It turns out there was a lot of debris left in the system lines, the sump and in the pump from a previous and unrelated test that the conventional spin-on filter failed to remove.

The debris was small enough (10 micron and under) to pass straight through the spin-on filter during the initial ‘cleaning’ process.

“It is obvious the Magnom is doing a much better job than the current spin-on filter in picking up damaging contaminants”.

Valvoline Application:

Mobile End-User Gearbox

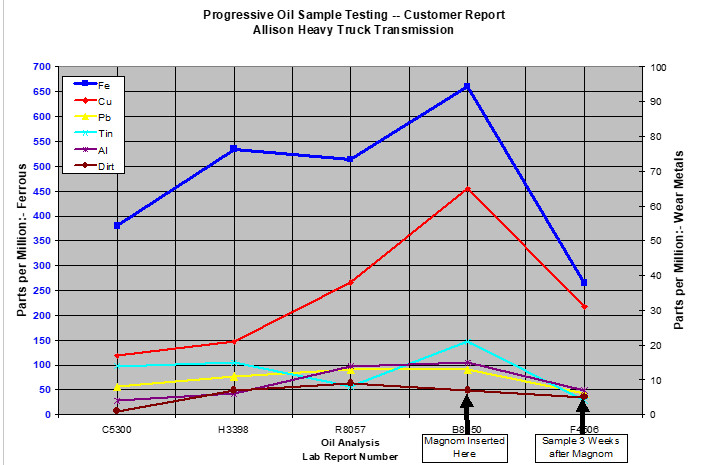

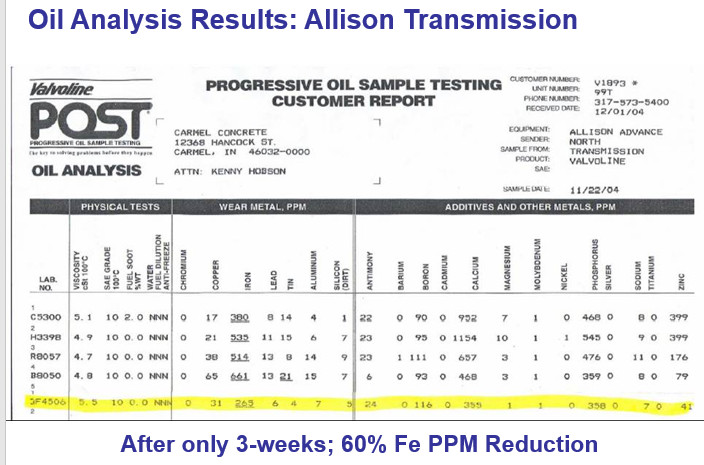

Allison Transmission Contaminant Removal Summary

Magnom utilised to filter transmission fluid on a heavy truck equipped with an Allison Transmission (automatic). •

Customer felt that periodic transmission overhauls were due to excessive wear and breakdowns caused by ferrous contamination. End-user’s independent supplier utilized Valvoline’s Progressive Oil Sample Testing service to obtain, track and record the data. The data from the report was transferred to a chart for easier reading on preceding page. The Magnom was inserted after the second to last sample. After 3 weeks time, the Magnom reduced the ferrous from 661 ppm to 265 ppm. This represents a 60% reduction in iron particulate.

Like the previous transmission report, a significant reduction in wear metals was observed. The Copper was reduced by 50%. The Lead was reduced by 50%. The Tin was reduced by 80% and the Aluminum was reduced by 50%.

Observing the ‘Additives and Other Metals, PPM’ section of the Oil Sample Report, we do not see any statistically significant change in any of the tracked Additives