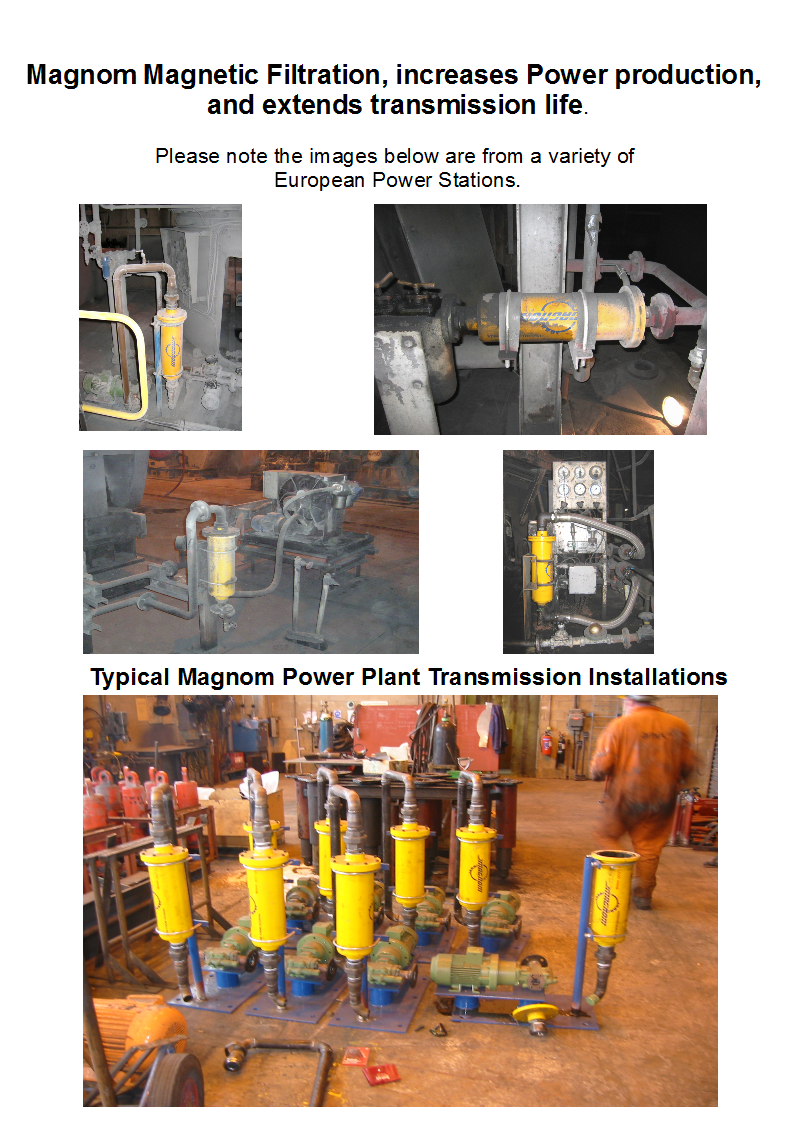

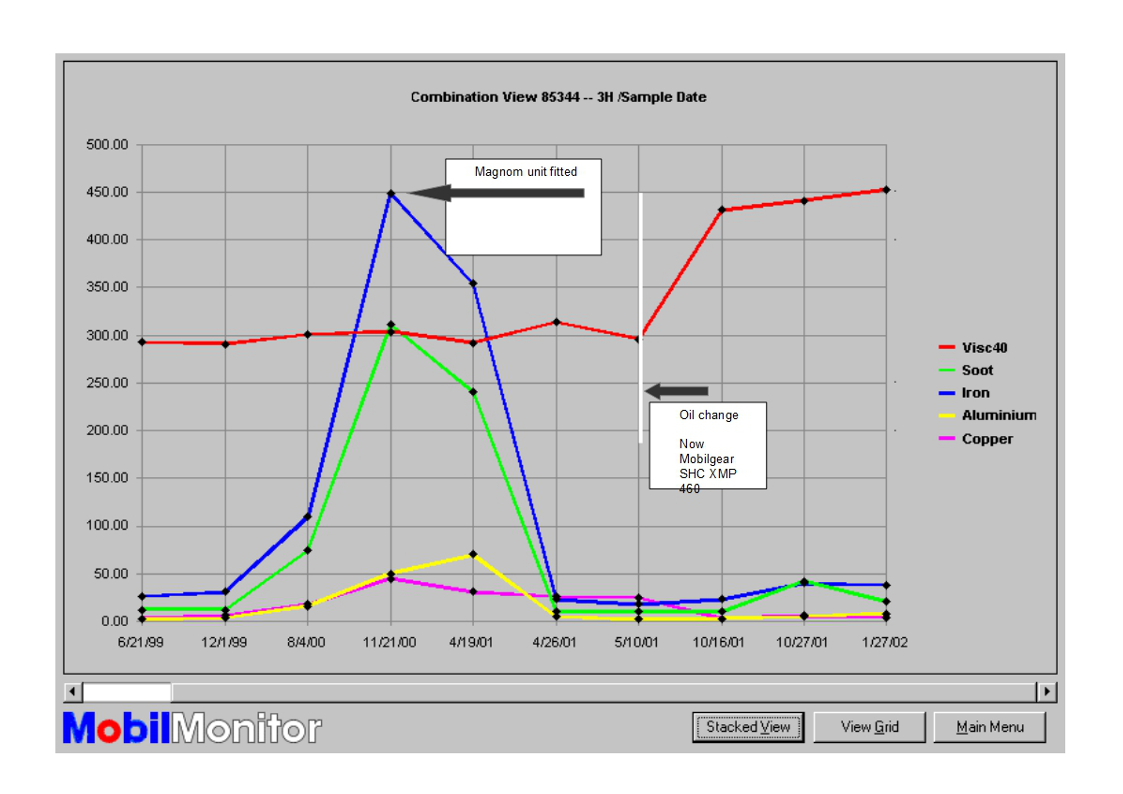

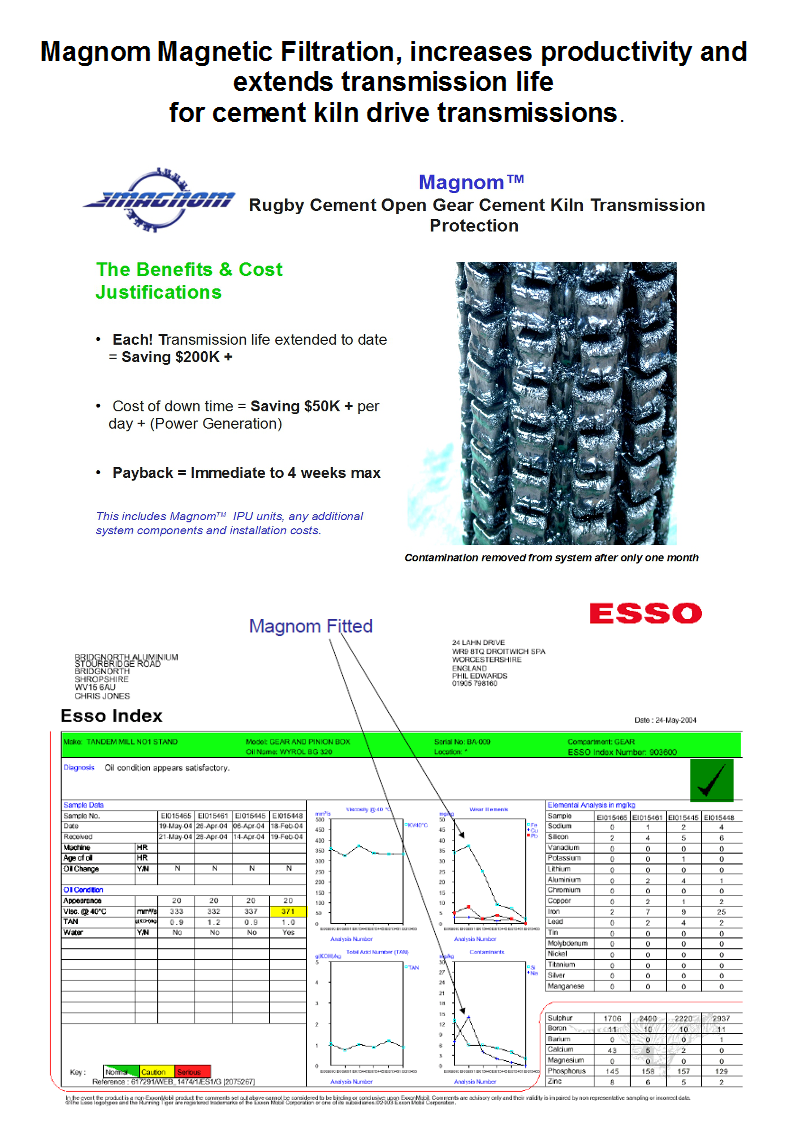

Magnom Magnetic filtration has been used/proven to clean highly viscous lubricating fluids used in power transmissions in Major Power stations in Europe (particularly coal powered), to protect the highly stressed transmissions, running 24/7, and to extend their production life, while massively reducing maintenance and repair costs.

While the reduction in maintenance costs was highly attractive the the Power Gen users, it was the extended availability for the transmissions to produce valuable power that was/is the main driving force for the plant wide adoptions of Magnom magnetic filtration.

These Power Gen Applications have seen the same benefits realised in a wide variety of transmissions,

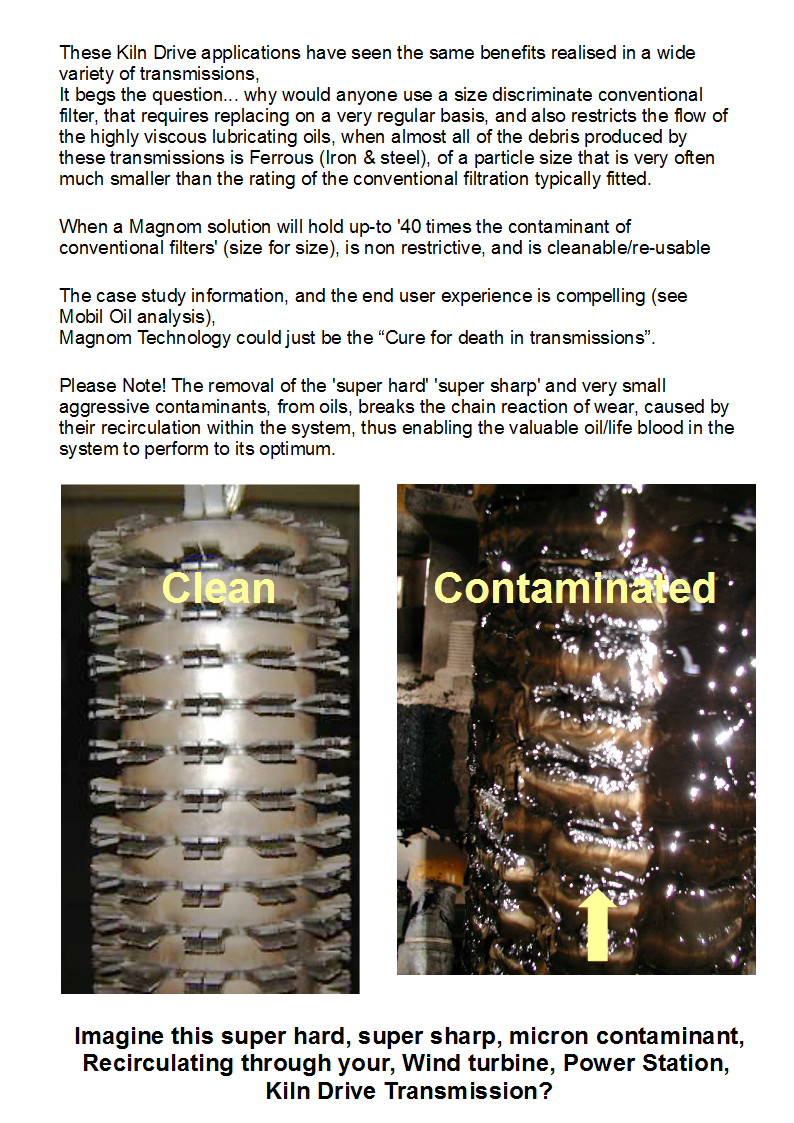

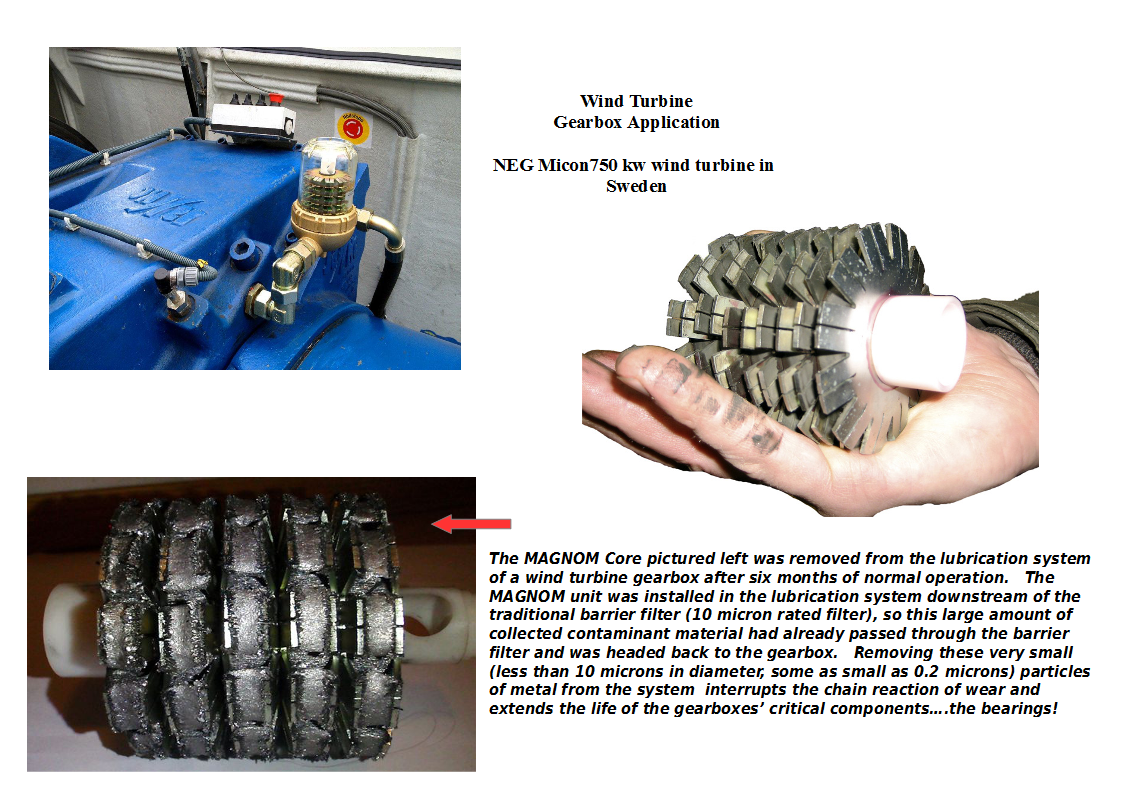

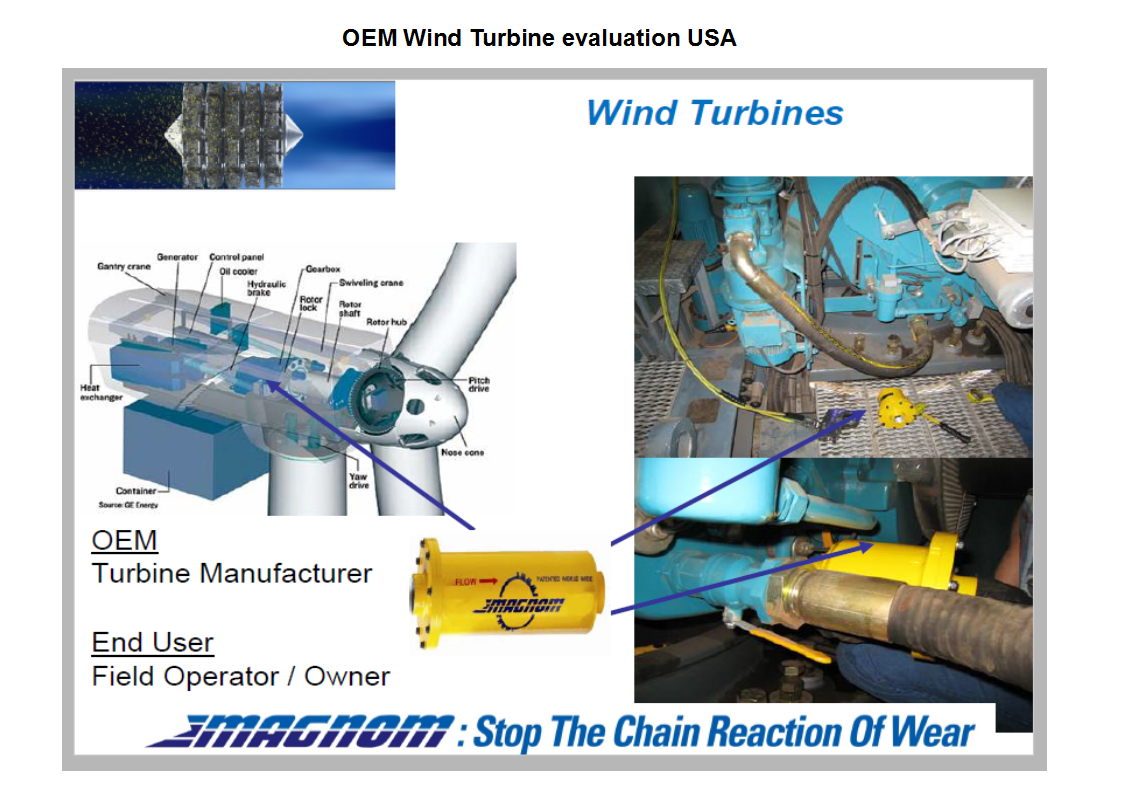

It begs the question… why would anyone use a size discriminate conventional filter, that requires replacing on a very regular basis, and also restricts the flow of the highly viscous lubricating oils, when almost all of the debris produced by these transmissions is Ferrous (Iron & steel), of a particle size that is very often much smaller than the rating of the conventional filtration typically fitted.

When a Magnom solution will hold up-to ’40 times the contaminant of conventional filters’ (size for size), is non restrictive, and is cleanable/re-usable

The case study information, and the end user experience is compelling,

Magnom Technology could just be the “Cure for death in transmissions”.