Magnom is a proven & patented filtration solution that filters down to less than 0.1 micron.

Typical tolerances for moving parts in fluid systems such as bearings, gears dynamic seals, valves and pumps can range from 0.2 to 5 microns. Magnom is effective for all critical particle size ranges.

Magnom filters have unsurpassed ability to remove microscopic ferrous particles from fluid systems irrespective of their location in the system. The patented core design ensures there is negligible pressure drop across the filter, so it can be used suction side of PD sensitive components.

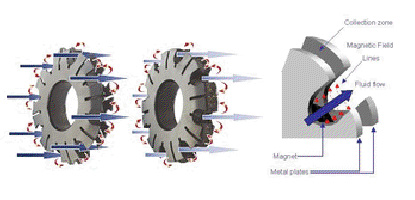

As with all good ideas, the patented Magnom core design is fundamentally simple. Fluids are cleaned of ferrous [iron & steel] particles by an intense magnetic flux field gradient. The strength and shape of the magnetic field is dramatically enhanced by the field effect of two metal lensing plates placed at either side of each magnetic core assembly. The enhanced field pulls the ferrous particles out of the fluid flow, without disturbing the fluid or its flow.

VIEW ANIMATION

The field effect lensing plates are have ‘V’ shaped flow channels cut out around their circumference these channels exceed the feed pipe diameter and so cannot impede flow. Each high energy magnet and its two flux field plates are known as a Magnom core. The fluid can only flow through the ‘V’ channels, and is therefore forced to pass through regions of high magnetic gradient – just what is required for effective cleaning!

Magnetic contaminants are captured in the space between the plates where they are held without risk of unwanted wash off (as is frequently the case with other magnetic devices).

These patented magnetic cores are typically stacked in multiples on a central mandrel, and located inside a snug fitting plastic or metal canister. The number of cores in a unit varies between 2 [for say Formula 1 cars] and 20 [for heavy duty industrial process protection]. The core diameter is designed and optimised to meet the flow conditions in the system.

To try to use a conventional barrier filter to achieve this level of performance would require a media so fine it would introduce massive pressure drop, and would very quickly fill, requiring a significant amount of costly replacement and maintenance.