Global OEM Independent Testing & Evaluation of Filtration

PROJECT SCOPE :-

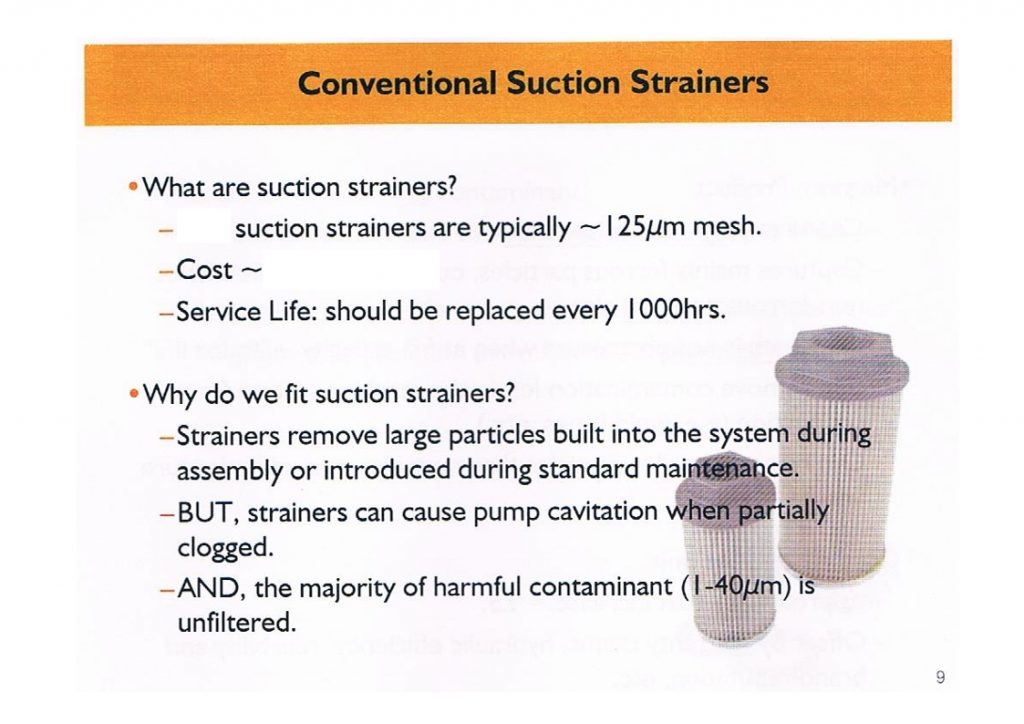

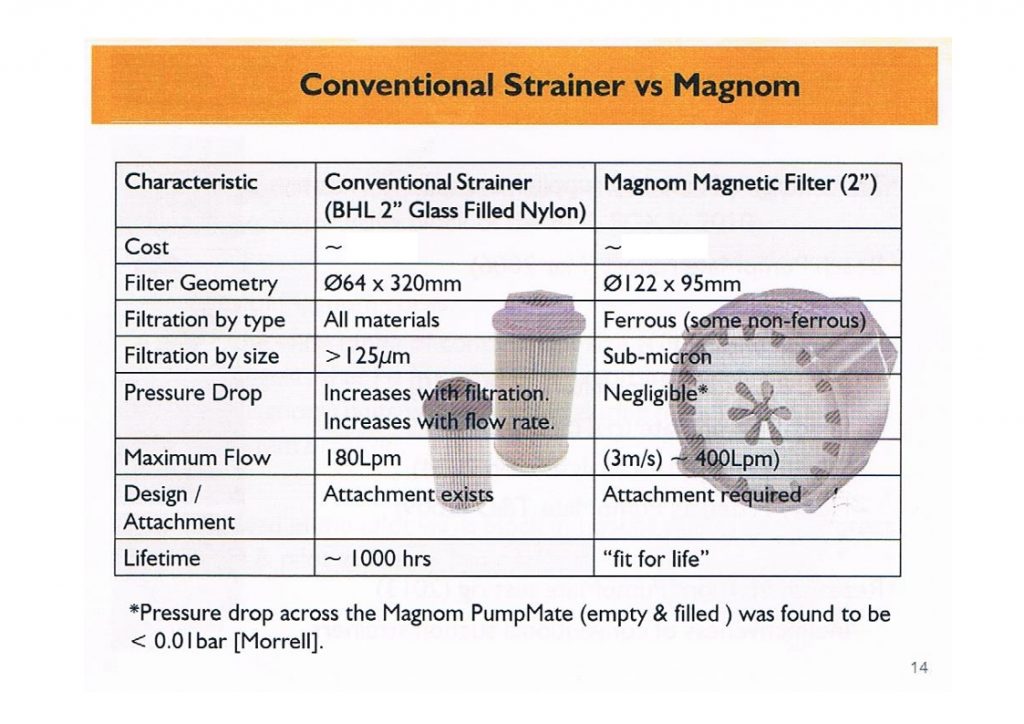

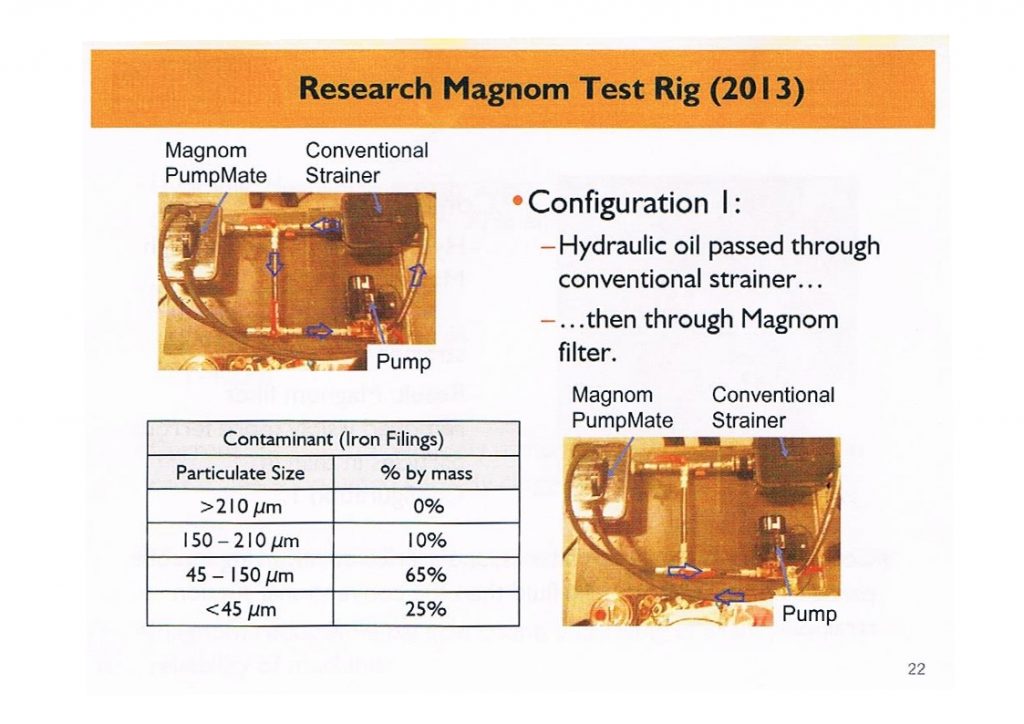

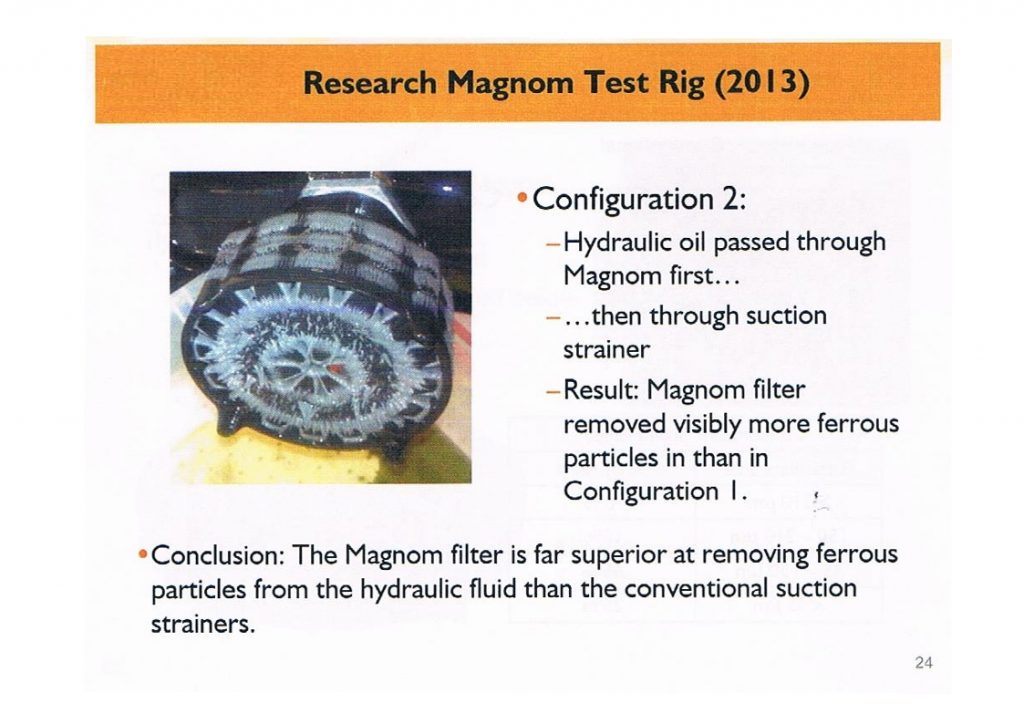

Evaluation of Magnom performance versus conventional suction strainers & –

Evaluation of total system cost.

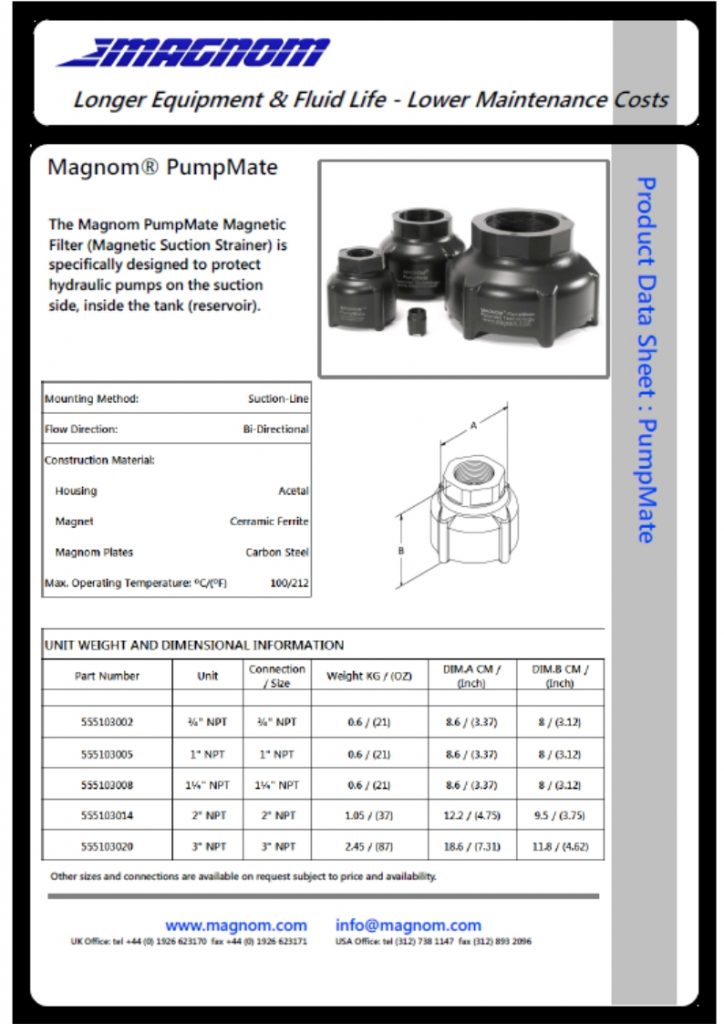

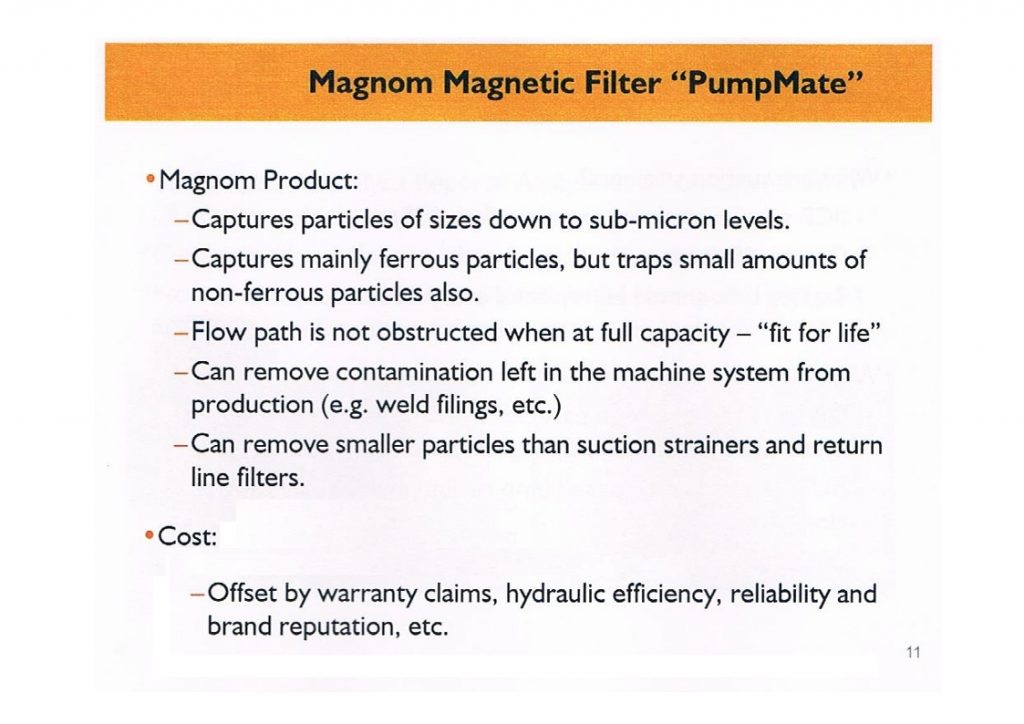

The Magnom PumpMate is :-

“Far Superior at Removing ferrous particles from the hydraulic fluid than conventional suction strainers”

Summary…

Compelling results for further OEM adoption of Magnom PumpMate

Conclusion :-

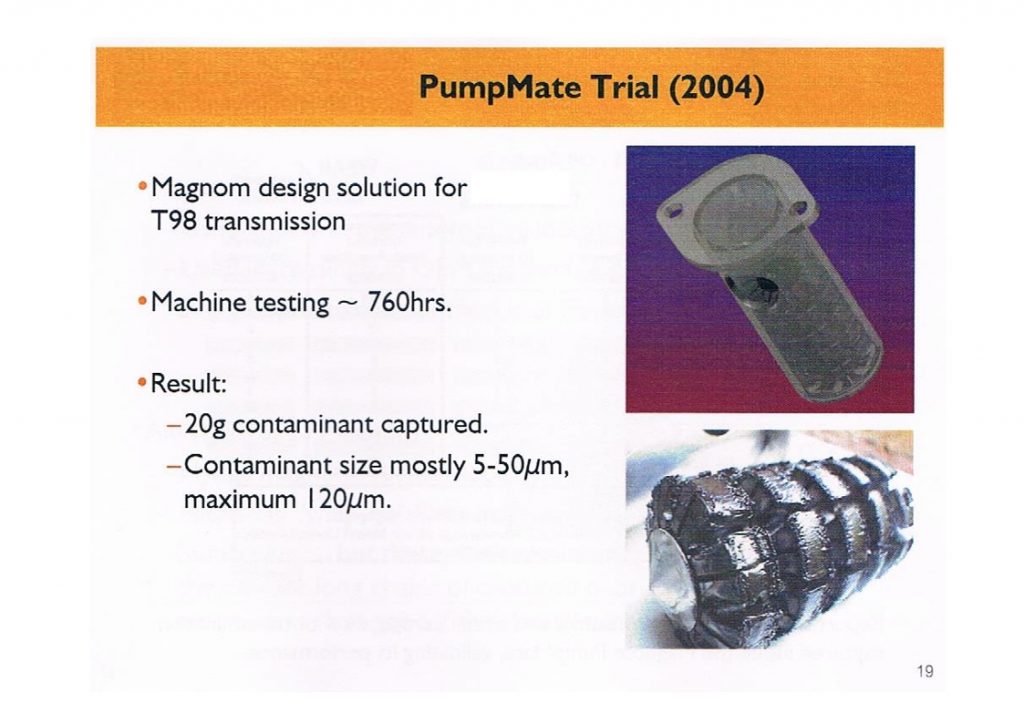

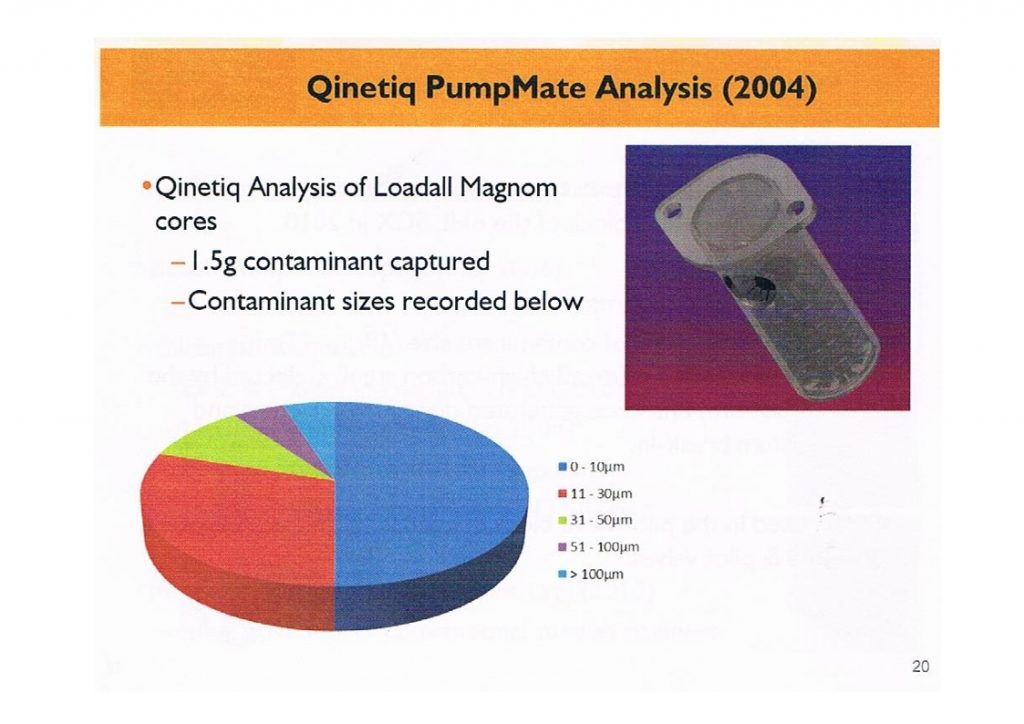

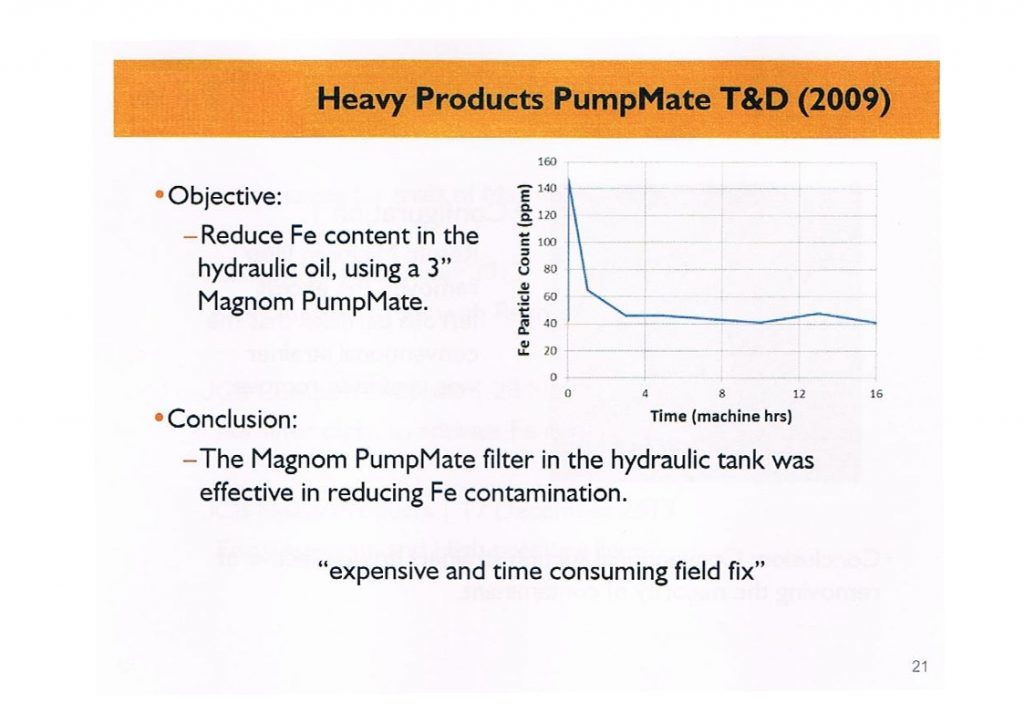

From historic experience and exhausting testing and analysis of these magnetic filtration products.

The Magnom filter is far superior at removing ferrous

particles from the hydraulic fluid compared to the conventional

suction strainers and should become a group standard.

Recommendation: Introduce Magnom PumpMate to

machines as part of NPIP programmes; replacing the conventional

suction strainer.

Compelling ???