The Ducati MotoGP team ‘Ducati Corse’ have been using Magnom magnetic filtration for almost a decade now.

Following a meeting some years ago now between the Magnom team and the man himself ‘Claudio Domenicali’, head of Ducati Corse (Racing) at the time, now CEO of Ducati.

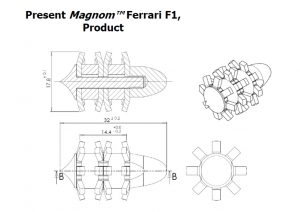

It was decided that a unique development of the Magnom magnetic filtration technology was to be developed for inclusion in the engine of the Ducati Corse MotoGP bikes.

The Magnom magnetic technology was especially developed for inclusion in the lubrication oil pick up pipe, in the sump of the Moto GP V 4 engines.

The objective was to remove any aggressive particulate from entering the power units main oil pump (without restriction to critical oil flow, a unique aspect of the Magnom technology), thus maximising the volumetric efficiency of the pump for the maximum possible time, and protecting the system as a whole from premature failure, caused by these contaminants.

i.e. Wear reduction, Longer service life, Extend component life, Extend oil life, Improve system performance as a whole.

This was initially driven by new rules in MotoGP,

Teams were to have a very limited number of engines for both qualifying and practice, so maximising the life and performance from this limited number of power units was indeed critical.

Protecting the systems critical components is obviously a major factor in achieving this.

Ducati motoGP engines have developed an unprecedented reputation for their power advantages and reliability during the period of use of the Magnom magnetic filter technology.

Magnom and Ducati have formed a strong relationship over the years, thanks in part to the advantages of using this unique technology.

Magnom magnetic filter techology can remove the most aggressive and problematic contaminant (Fe.. Iron/steel, ferritic materials), down to 0.07 of a micron, without restriction to fluid flow (EVEN WHEN FULL OF CONTAMINANTS) and once removed, trap them out of the fluid flow, avoiding wash-off and reintroduction to critical systems.