Variable Piston Pumps ‘VP Pumps’ along with more conventional pumps, have to ingest contaminants from the reserviour that pass return line filtration.

Historic use of mesh/suction filters has been proven to cause cavitation and premature pump failure.

Thus these typical suction strainers have to be made of very course mesh, rendering them unable to stop the damaging contaminants from entering the pumps and system.

Such is the problem with the historic use of these strainers that, this has seen Bosch Rexroth refuse warranties on systems using mesh suction filters.

But innovation has moved on, in conjunction with Magnom Corp, rexroth set out to test and understand the value of Magnom’s Magnetic Suction separator “The PumpMate”.

It will not be a surprise to hear that removal of ‘super hard’, ‘super sharp’ micronic particulate from systems can have a huge benefit for the systems.

Aggressive contaminants removed Pre-Pump

The Magnom PumpMate acheives this function:-

1, Pre Pump protection

2, To sub micron levels

3, Is non restrictive (no cavitation issues)

4, Is potentially fit for life (massive capacity so, no servicing required)

5, Flows as much fluid when full of contaminant, as when empty.

6, Low cost

7, No bigger than a suction strainer.

In testing carried out by REXROTH, the system fitted with the PumpMate hit “NAS 3” cleanliness,

The unit even removed some non ferrous contaminants (See analysis below).

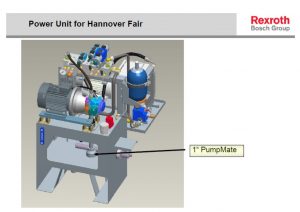

So impressed were REXROTH, they committed to feature the PumpMate product on their stand at the Hanover Fair, in Germany.

PumpMate was also awarded the coverted REXROTH ‘AB’ standard for best practice product.

We know of no other filtration/separator that can be fitted to the suction side of a Pump without risk of invalidating warranty

REXROTH At Hanover, & the REXROTH Prototype PumpMate